Why Fixaball?

Over 50 years of fastener and fixing experience.

We stock 100,000+ different fixings and fasteners.

Our delivery systems are efficient and reliable. Fast wordwide shipping.

Our prices are updated regularly to remain competitive.

Fully traceable EU Sourced materials.

ISO 9001:2015.

Certification including C.O.C, 3.1, Raw materials, Plating.

Fasteners to any international

standard BS, DIN, ISO, ANSI or to Drawing.

Manufacturing in all materials incl, high grade alloys, Stainless, Brass etc.

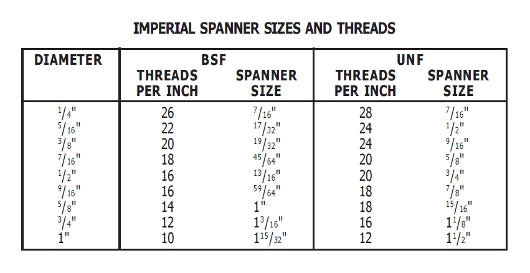

From 2mm up to 64mm diameters in all threads, Metric, Metric Fine, Historical and American Imperial sizes.

We can manufacture and supply quantities from a handful to many thousands.

Engineering Fasteners

Construction Fixings

Chemical Anchor Studs

The drill bit diameter is the same as the thread diameter. This...

Cavity Wall Anchor

Cavity Wall Anchors Here at Fixaball, we stock all sizes, materials and...

-

Review

Excellent service, ordered AM Wednesday delivered PM Thursday.

Thanks, E Jones -

Review

Regularly use these guys for all my fixings.They’re always well stocked and deliver on time. Tux Mark Tucker

-

Review

BRILLIANT SERVICE FROM START TO FINISH.

THANK YOU SAM FOR GOING ABOVE AND BEYOND TO HELP.!!!!!

Featured Products

-

0BA x 1.1/2" Socket Cap Screw High Tensile 12.9 DIN 912

Regular price From £20.20 GBPRegular priceUnit price per£0.00 GBPSale price From £20.20 GBP -

1/2" BSF Socket Screw Button High Tensile 10.9 Self-Colour

Regular price From £2.94 GBPRegular priceUnit price per -

1/2" BSW Whitworth Hex Bolt High Tensile R/ 8.8 Self-Colour

Regular price From £9.81 GBPRegular priceUnit price per -

1/2" Internal Shakeproof Washers Steel Self Colour

Regular price From £5.40 GBPRegular priceUnit price per -

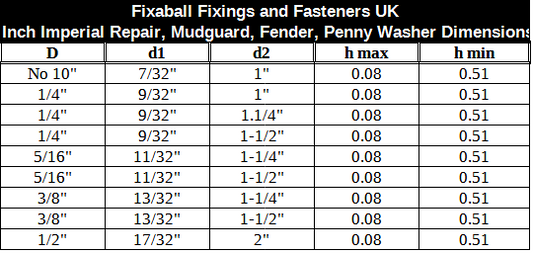

1/2" Penny Repair Washers A2 304 Stainless Steel DIN9021

Regular price From £3.30 GBPRegular priceUnit price per -

1/4" 5/16" 7/16" Mudguard Repair Penny Washers BZP Zinc DIN9021

Regular price From £2.39 GBPRegular priceUnit price per -

1/4" BSF Socket Screw Button High Tensile 10.9 Self-Colour

Regular price From £3.68 GBPRegular priceUnit price per -

1/4" Dowel Pins Hardened/ Ground Steel ANSI B18.8.2

Regular price From £3.17 GBPRegular priceUnit price per -

1/4" Penny Repair Washers A2 304 Stainless Steel DIN9021

Regular price From £2.80 GBPRegular priceUnit price per -

10mm Dowel Pins A1 Stainless Steel DIN 7

Regular price From £6.15 GBPRegular priceUnit price per -

10mm Dowel Pins Hardened & Ground Steel DIN 6325

Regular price From £4.14 GBPRegular priceUnit price per -

10mm Hex Nut Sleeve Masonry Concrete Anchor Zinc

Regular price From £3.30 GBPRegular priceUnit price per