Large Flange - Blind Rivet

4.8mm Pop Blind Rivets Large Flange Aluminium

4.8mm Pop Blind Rivets Large Flange Aluminium

Couldn't load pickup availability

Postal Notification: Royal Mail 48 delivers between 2-3 days, 97% of the time. Choose 1st or tracked at checkout for time sensitive shipments.

4.8mm, Blind/ ‘Pop’ Rivets, EXTRA Large Flange, Aluminium/ Steel Mandrel (zinc plated)

Fixaball sell all lengths of 4.8mm Diameter, Extra Large Flange, Pop/ Blind Rivets.

EXTRA Large Flange Rivets

EXTRA Large Flange Rivets are used in a multitude of industries such as aerospace, automotive, rail, HVAC, white goods, electronics, DIY and general engineering.

- Body Material - Aluminium (AlMg2.5).

- Mandrel Material - Steel Zinc & Clr Tri3.

- EXTRA Large flange, blind rivets normally used with a washer, for joining softer materials. The extra large flange and washer distributes the load better without damaging the joined materials.

- Aluminium body with zinc plated steel mandrel.

Orders placed before 2pm are dispatched same day (Mon-Fri).

Standard, Free Delivery is Royal Mail, 2nd Class (2-5 days, most likely 2 days). For a faster delivery time, select 1st class or courier at checkout.

Please make your size and pack quantity selection from the drop down menus.

Extra Large Flange, Pop/ Blind Rivets Diameter: 4.8mm.

Extra Large Flange, Pop/ Blind Rivets Lengths:

| 4.8 X 10 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 12 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 14 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 16 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 18 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 20 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 22 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 24 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 26 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 28 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 35 Aluminium / Steel Large Flange Head Rivets |

| 4.8 X 40 Aluminium / Steel Large Flange Head Rivets |

Installation

The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel into the rivet. This expands the blind end of the rivet and then the mandrel snaps off. Unlike solid rivets, blind rivets can be inserted and fully installed in a joint from only one side of a part or structure, "blind" to the opposite side. Due to this feature, blind rivets are used mainly when access to the joint is available from only one side. The rivet is placed in a drilled hole and is set by pulling the mandrel head into the rivet body, expanding the rivet body and causing it to expand against the reverse side. As the head of the mandrel reaches the face of the blind side material, the pulling force is resisted, and at a predetermined force, the mandrel snaps at its break point. A tight joint formed when deformation of the rivet occurs when joining parts are held tightly. The mandrel is removed before inserting another rivet.

Removal

Drill through where the mandrel was removed

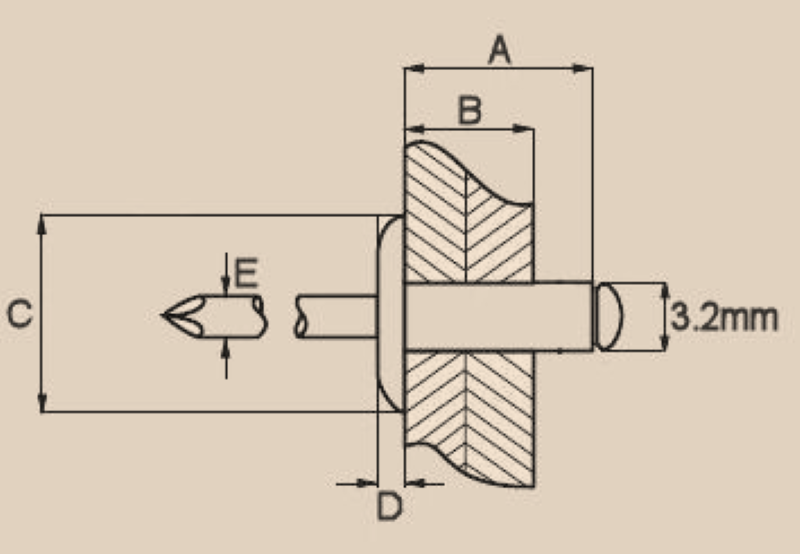

Please see images for large flange, blind rivet’s specifications/ dimensions

Image is for illustrative purposes only.

Materials

Materials

Shipping & Returns

Shipping & Returns

Fixaball, UK Shipping

Standard, Free Shipping at Fixaball is Royal Mail 48 (2-3 days). Shipping upgrades are available at checkout; please see the table below.

Postal Notification (Nov-Dec 2023): Royal Mail 2nd Class delivers between 5-10 days, 5% of the time. Choose 1st or tracked at checkout for time sensitive shipments.

Same day shipping courier available on request.

Handling Time

All orders are shipped the same day if ordered before 2pm, Monday to Friday, excluding weekends and bank holidays.

| Value of Order | Shipping Service Type of Shipping | Speed of Shipping | Cost of Shipping |

| All Values | Royal Mail 48 | 2 - 5 Working Days | Free |

| £0 - £40 | Royal Mail Tracked 48 | 2 - 5 Working Days | £3.5 |

| £40 | Royal Mail Tracked 48 | 2 - 5 Working Days | Free |

| £0 - £10 | Royal Mail 24, | 1 – 2 Working Days | £3 |

| £10.01 - £25 | Royal Mail 24, | 1 – 2 Working Days | £4 |

| £25.01 - £29.99 | Royal Mail 24, | 1 – 2 Working Days | £6.5 |

| £0 - £20 |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 5pm | £10 |

| £20.01 - £40 |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 5pm | £12.5 |

| £40.01 - £120 |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 5pm | £16.5 |

| £120 - £220 |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 5pm | £20 |

| £220 - £330 |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 5pm | £30 |

| £300+ |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 5pm | £30 |

| All Values |

Next Working Day, Tracked. MAINLAND ONLY |

Next Day, Before 1pm. |

CALL or Email 01242522244 sam@fixaball.co.uk |

Royal Mail's retail compensation policy for loss

At Fixaball we will do everything possible to make sure our delivery/ despatch times are met, as reliability is our top priority. Royal Mail and DHL are fantastic shipping providers but on very rare occasions shipping will arrive late. Please select postage upgrades on shipping that is time sensitive. On even rarer occasion, mail is lost. Royal Mail allow 10 working days before they class post as 'lost'. After which time we can request compensation. Please see the table below.

|

Product |

Due Date |

Compensation for loss payable |

|

1st class- stamp/meter/account (Including Royal Mail Signed For ® sent as 1st class) Online Postage, Articles for the Blind |

Next working day after posting |

10 working days after due date |

|

2nd class - stamp/meter/account (Including Royal Mail Signed For® sent as 2nd class), Online Postage |

3 working days after posting |

10 working days after due date |

|

Royal Mail Special Delivery Guaranteed by 1pm ® (not posted on account)

|

On guaranteed date as per product specification

|

5 working days after due date

|

My item is shown as delivered but it hasn't been?

What can I do if my item is shown as delivered, but it hasn’t been received?

If you’re the recipient:

Check whether the item was sent using a service that obtains a signature on delivery. If it was, do you recognise the name of the person who accepted the item? The name will be provided by the person who accepted the delivery and not always the person on the address label.

If the item was sent to your home, ask anyone else living there if they accepted the delivery. Please also check if the item has been left with a neighbour, or in your designated Safeplace if you have one.

If the item was sent to your work address, check with the post room and your colleagues to see if someone accepted the delivery.

If you bought the item online, check the shipping address was correct.

UPS - Packages over 2 kgs

We use UPS as our preferred courier. Please make sure all details of the address are included as courier drivers will not fill in the gaps, leading to long delays or even loss

Fixaball, International Orders.

Offshore and International Shipping

We use Royal Mail, Airmail, Tracked & Signed for international orders. However, if the order exceeds the maximum weight (2kg) we will use UPS. Often, discounts can be offered on light weight/ high value goods if you email or call. Also, faster delivery can be arranged on your request. The dispatch window for all of our offshore sales is 1 working day (most likely same day dispatch if ordered before 2pm).

Our delivery services are reliable; however, occasionally there may be a delay due to various unforeseen circumstances (weather, industrial action, holiday seasons). With this in mind, please consider feedback based on what we can control, which is our quick, dispatch time (same day if ordered before 2pm). Our aim is to do everything we can to support you.

|

Fixaball International Shipments: 3-5 days to the country + Customs Clearance |

||||||

|

Total Value of Your Purchase |

||||||

|

(Exchange Rate Will Change With the Global Exchange Rate) |

||||||

|

Pound Sterling |

£0 - £20 |

£21- £40 |

£41 - £120 |

£121 - £200 |

£201 - £300 |

£300.00 |

|

Euros |

€0 - €23 |

€24 – €46 |

€47 – €138 |

€139 – €229 |

€231 – €345 |

€346 |

|

|

||||||

|

Zone 1 England Scotland Wales |

||||||

|

Pound Sterling |

£6.00 |

£7.50 |

£9.00 |

£12.50 |

£20.00 |

£30.00 |

|

Euros |

€6.9 |

€8.6 |

€10.5 |

€14.5 |

€23 |

€35 |

|

|

||||||

|

Zone 2 Northern Ireland |

||||||

|

Pound Sterling |

£6.50 |

£8.00 |

£9.50 |

£13.00 |

£25.00 |

£40.00 |

|

Euros |

€7.5 |

€9.2 |

€11 |

€15 |

€29 |

€46 |

|

|

||||||

|

Zone 3 Belgium, France, Germany, Republic of Ireland, Luxembourg, Monaco, Netherlands |

||||||

|

Pound Sterling |

£10.00 |

£15.00 |

£25.00 |

£35.00 |

£50.00 |

£80.00 |

|

Euros |

€11.5 |

€17.5 |

€29 |

€40 |

€58 |

€92 |

|

|

||||||

|

Zone 4 Austria, Azores, Czech Republic, Denmark, Finland, Greece, Italy, Madeira, Poland, Portugal, Spain, Sweden |

||||||

|

Pound Sterling |

£12.00 |

£18.00 |

£30.00 |

£45.00 |

£70.00 |

£100.00 |

|

Euros |

€14 |

€21 |

€35 |

€52 |

€81 |

€115 |

|

|

||||||

|

Zone 5 Bulgarian, Croatia, Cyprus, Estonia, Hungary, Latvia, Lithuania, Malta, Romania, Slovakia, Slovenia |

||||||

|

Pound Sterling |

£15.00 |

£20.00 |

£32.00 |

£50.00 |

£80.00 |

£120.00 |

|

Euros |

€17.5 |

€23 |

€40 |

€58 |

€92 |

€138 |

|

|

||||||

|

Zone 6 Albania, Andorra, Belarus, Bosnia and Herzegonia, Ceuta, Faroe Island, Gibraltar, Greenland, Guernsey. Iceland, Jersey, Kosovo, Liechenstein, Macedonia, Moldova, Montenegro, Norway, Russia, San Marino, Serbia, Switzerland, Turkey, Ukraine |

||||||

|

Pound Sterling |

£20.00 |

£25.00 |

£35.00 |

£55.00 |

£85.00 |

£125.00 |

|

Euros |

€23 |

€29 |

€41 |

€64 |

€98 |

€145 |

|

|

||||||

|

Zone 7 Contact us Directly for a Bespoke Quote Canada, Mexico, Puerto Rico, United States |

||||||

|

Zone 8 Contact us Directly for a Bespoke Quote China, Hong Kong, Indonesia, Japan, Macau, Malaysia, Phillipines, Singapore, South Africa, South Korea, Taiwan, Thailand, UAE |

||||||

|

Zone 9 Contact us Directly for a Bespoke Quote Australia, New Zealand |

||||||

|

Zone 10 Contact us Directly for a Bespoke Quote Rest of the World |

||||||

Dimensions

Dimensions

Share

-

Free Shipping

Shipping PolicySame Day Despatch

All prices shown include VAT and Free, 2nd Class Royal Mail Shipping.

Upgrades Available

Signed For and Tracked

1st Class Royal Mail

DHL Next Day Courier (before 11pm and 1pm available)

-

Hassle-Free Refunds/ Exchanges

Refund/ Return PolicyReturn your Item within 30 days for a 'no quibble' (no reason) refund